When I create a UNC thread in the model. They were just simple stepped reducers that were turned down.

Iso Surface Roughness Symbols Terminology

Its intention is to describe hand gripping aid knurls.

. To deal with this surface measurement is typically divided into three regions. Roughness affects various part characteristics including the amount of wear the ability to form a seal when the part makes contact with something and the ability to coat the part. Surface finish refers to the process of altering a metals surface that involves removing adding or reshaping.

I mean you could see the tear marks where the tool was plowing the material off. A polished surface can be a datum and is often the best choice. Definition GDT Clarification - Callout for Profile of a Surface Reference to the Datum.

Click Insert Surface Finish. Surface Finish - Callout as 8 - 16 Rq. Are indicated around the surface symbol as shown in Fig.

Roughness waviness and form. The tolerances were fine but surface finish was the worst I EVER saw. A symbol for defining the surface finish of a part.

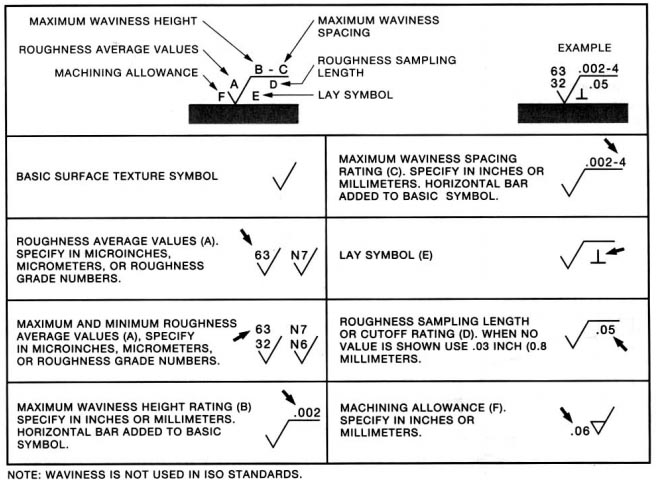

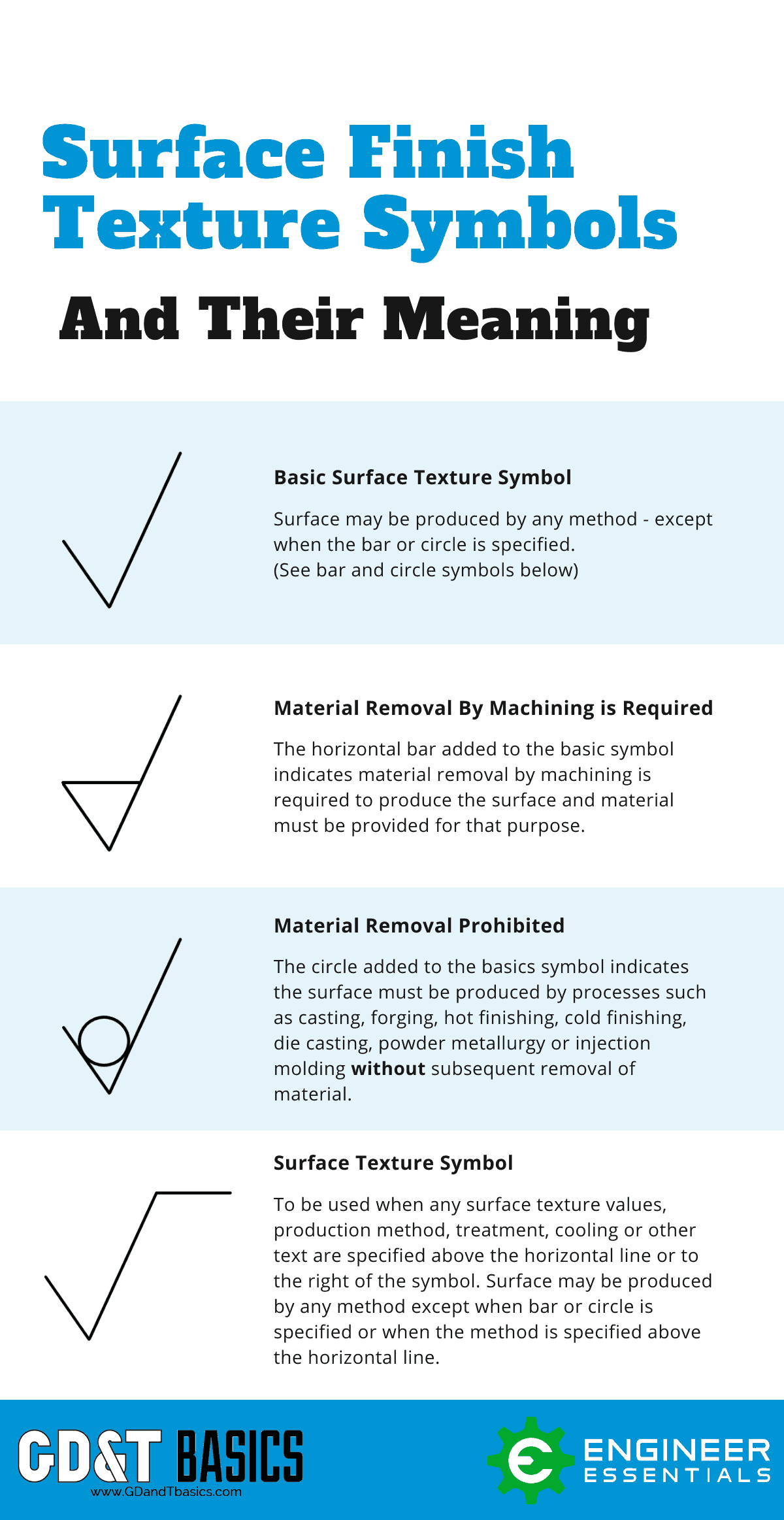

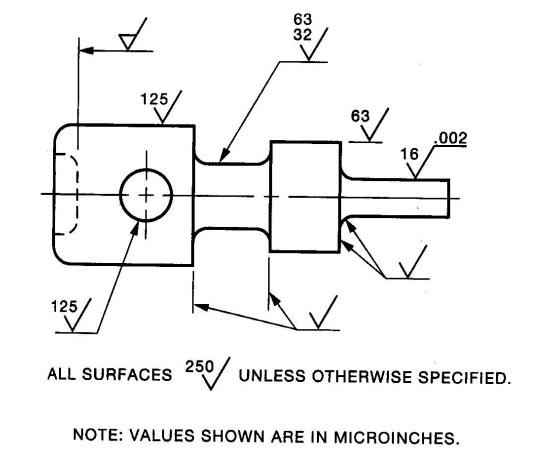

There are many variations of the surface texture symbol but most often it is used with a microinch or micrometer value callout that specifies the roughness of a surface. The problem is simple. A surface roughness value cut-off value or reference length processing method grain direction surface undulation etc.

I cant make the little surface finish triangle leader but basically its 25 then in parenthesis 63. Complete Guide to Surface Finish Charts RA RZ Measurements Callouts and Symbols. It is a measure of the complete texture of a products surface that is defined by three characteristics of surface roughness waviness and lay.

Select one of the following. It is the symbol that means all surfaces around a workpiece outline. One of our local vendors ex-vendor now BTW recently did some 303 SS parts for us.

The European standard for knurls is DIN 82. Can you tell us the Ra equivalent of this value. As Ethan48 says for fitting you need a more precise definition at least for the outer surface diameter cylindricity runout etc.

Engineering prints call out a great many things in their attempt to make sure the part that gets made matches the designers intent. Part 7 covers surface imperfection tolerances. Profile of a Surface Callout on this Drawing.

Surface Roughness Finish Surface roughness - a measurable characteristic based on roughness deviations Surface finish a subjective term Arithmetic Average AA Ra arithmetic mean value of roughness y the vertical deviation from nominal surface L mthe specified distance Root-mean-square RMS the square root of the mean of the squared deviation over. See figures below for examples. The length of a measurement is a critical part of specifying surface roughness.

NameSelects a symbol from the SYMBOL NAMESmenu containing a list of symbols that are currently in the drawing. Surface Finish is a measure of the overall. In the drawing just the inch dimensions are shown but not written which thread like UNC etc.

I have to two questions about the drawing standard. Symbols Used In GDT Callouts. Drawing Standards thread callouts surface finish symbol production.

We have a furnace roll on the technical drawing and the surface roughness value of this roll is represented with CRODAN 3 or CRDDAN 3This is the surface roughness value of grounded and sandblasted condition of the piece. Aside from dimensions and tolerances another important callout is Surface Finish. Surface finish would describe processes like anodizing electroplating or painting.

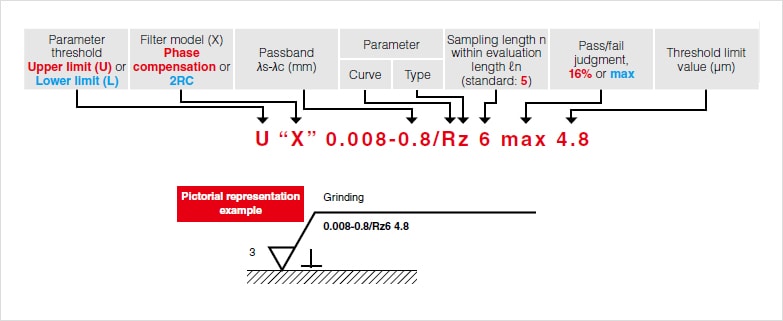

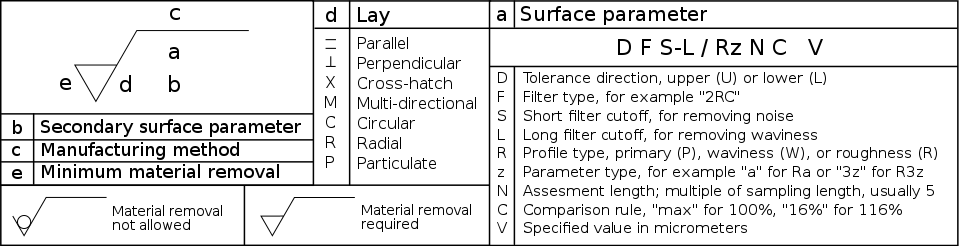

The principal ISO standard that specifies surface roughness is ISO 1302 and defines the surface roughness symbology and additional requirements for engineering drawings. I tried to add entries in the. Definition of Surface texture and Stylus instrument Profile by Stylus and phase correct filter ISO4287.

For some situations having a surface that is too smooth is not acceptable. Datum and the surface. We have no idea what CRODAN 3 is.

The inch version is approx 250. Manufacturing and Related Processes. The indication is always the same for each surface but the method of indicating the datum follows mechanical drawing practice.

96 Evaluation procedure of roughness ISO4288. General Measurement Device and Calibration Topics. Manufacturing SpecificationSurface Roughness Review.

Pick InstSelects a symbol by. You can select the face in a part assembly or drawing document. The standard includes a proposed drawing representation as well.

96 Upper limit - the 16 rule Default Lower limit - the 16 rule shown as L Max value - the max rule when max suffix is added. When the same surface texture is required on all surfaces around a workpiece represented on an orthographic 2D drawing by a closed outline a circle is added to the symbol at the junction of the tick and the horizontal line Figure 613e. You can take measurements over 01mm 1mm or 10mm with the same instrument and get completely different answers for the same surface roughness measurement.

Surface finish callouts on drawings. The surface roughness is the measure of the total spaced irregularities on the surface. For ISO and related drafting standards you can display surface finish symbols per 2002 standards by selecting Display symbols per 2002 in Document Properties Surface Finishes.

Surface finish symbols are formed by combining the Symbol and Lay Direction direction of lay. The details in ISO surface finish standards relate to surfaces produced by abrading casting coating cutting etching plastic deformation. With some threads it works on what does this depend.

Drawing Indication of Surface Texture. Surface texture callouts can be very complex or very simple depending on what is required in the finished product. Under ISO 1302 a finish range should be indicated as e in Fig.

The callout is 5NxA and is similar to that of Part 3. How to interpret surface finish callout. And surface roughness would not include characteristics like waviness or lay.

The 63 would be the metric callout. The GET SYMBOLmenu appears. KEYENCEs Introduction to Roughness website introduces parameters and case studies related to such surface measurements.

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Dimensions Surface Finish Roy Mech

The Basics Of Surface Finish Gd T Basics

Understanding Surface Roughness Symbols Introduction To Roughness Keyence America

Surface Finish Surface Roughness It S Indications Symbols

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Roughness Symbol In Drawings Mechanical Engineering General Discussion Eng Tips

0 comments

Post a Comment